In October 2014, imec joined the Graphene Flagship, a European Future and Emerging Technology Flagship initiative set to take ‘wonder graphene’ and related layered materials from academic laboratories to everyday use. Within this 1 billion euro initiative, Cedric Huyghebaert from imec coordinates the activities on the wafer-scale integration of graphene. In this article, he talks about the game-changing potential of graphene, about the challenges towards commercialization and about working within the context of a European Flagship.

The Graphene Flagship

In 2013, Europe launched a new initiative: the Graphene Flagship. Along with the Human Brain Project, it is the first of the European Commission’s Future and Emerging Technology (FET) Flagships. Their mission is to address the big scientific and technological challenges of this age through long-term, multidisciplinary research and development efforts.

Cedric Huyghebaert: “A Flagship finances longer-term research – typically within a time horizon of 10 years – and wants to make an impact on industry and society. Flagships are assigned to those fields where Europe is leading or at least state-of-the-art. Graphene was originally made and tested in Europe, leading to the 2010 Nobel Prize in Physics for Andre Geim and Konstantin Novoselov from the University of Manchester.”

Imec joined the Graphene Flagship in October 2014. Cedric Huyghebaert: “Initially, the partners of the Flagship were predominantly coming from academia and research institutes. After a new competitive call in 2014, the share of companies, mainly SMEs, largely increased. This shows the growing interest of economic actors in graphene and reflects the final goal of the project: turning scientific research into marketable products, and generate economic growth, new jobs and new opportunities.”

Today, over 150 academic and industrial partners from more than 20 countries take part in the Flagship. With a budget of 1 billion euro over 10 years – partly financed by national funding agencies – the Graphene Flagship is Europe’s biggest research initiative ever. It is coordinated by Chalmers University of Technology (Sweden).

Wonder material

The Flagship is all about graphene, a crystalline monolayer of carbon atoms arranged in a hexagonal honeycomb lattice structure. Graphene is a fantastic electronic and thermal conductor. It has a record thermal conductivity, a very big intrinsic mobility, a high current density and long mean free path of electrons. Its surface is chemically inert, it has a low surface energy and no out-of-plane dangling bonds. Moreover, this 2D crystal is flexible, transparent and it is the strongest material known to man. In short: a wonder material... And due to these exciting properties, opportunities emerge in a variety of domains.

Cedric Huyghebaert: “Graphene can be used to reinforce composites and coatings, or make them lighter – think of bicycles or an aircraft wing for example. It also has potential in energy storage or photovoltaic applications, where it could be used as an alternative (transparent) electrode. Researchers are also screening its potential for flexible electronics. And in chip technologies, it could replace copper wires in back-end-of-line interconnects. In biomedical applications, the material’s biocompatibility is an important asset, making it suitable as a probe material. It could potentially be used in bio-sensing applications as well, thanks to its ability to adsorb and desorb various atoms and molecules. And finally, graphene is finding its way into photonic and optoelectronics applications where light is used for transporting large amounts of data. Graphene turns out to be very beneficial for converting digital signals into light modulation. It has a fast tunable absorption over a wide spectral range, and promises a simple structure with only one integrated layer.”

Within the Graphene Flagship, all these potential applications are organized and researched in various work packages. Besides work packages on research and innovations, the Flagship also looks into the impact of the technology on health and environment. And since the launch of the project, the scope has broadened to include other 2D materials as well, in the form of 2D crystals or combined into Van der Waals heterostructures.

Wafer-scale integration

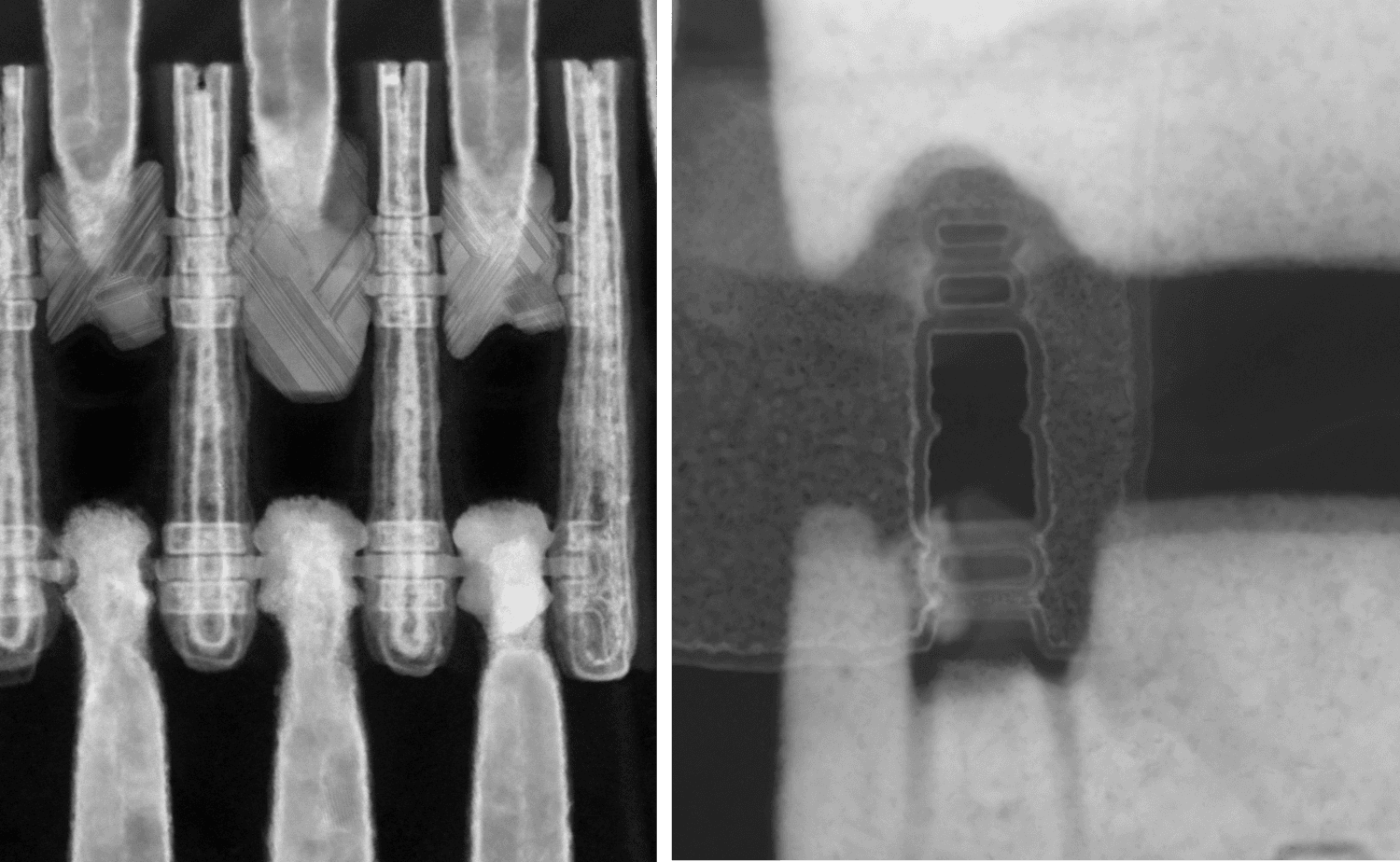

Together with CNIT, Italy, imec is leading the work package on wafer-scale integration. This work package targets the transition from laboratory to wafer-based microfabrication technology. Cedric Huyghebaert: “Many graphene-based concepts have been successfully demonstrated. But most of the demonstrations are limited to the lab and use graphene in the form of small exfoliated flakes. The real challenge is to mature these concepts from flake-based devices towards real marketable products. And this requires the integration of the material at the wafer scale, in a real production environment. This flake-to-wafer transition will be crucial to progress towards industrial applications in the fields of electronic devices, biomedical technology, sensor devices and opto-electronics.”

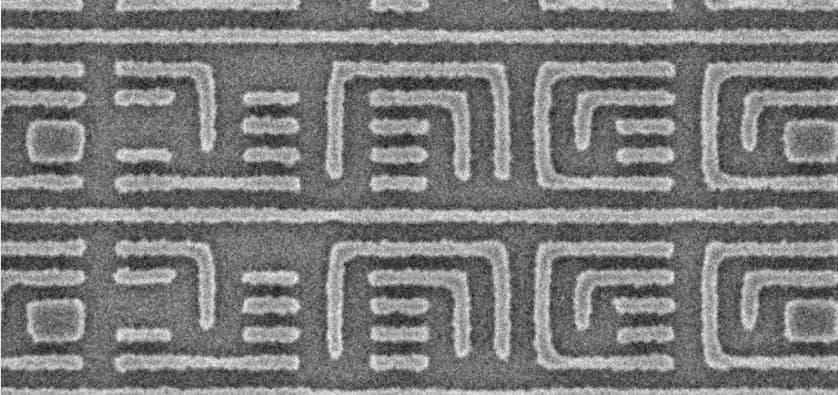

The road towards manufacturability involves the growth of graphene on large area templates, and the transfer to the target substrates. Graphene is typically grown on a metal template (such as copper) at very high temperatures – up to 1000°C. For this growth process, the quality of the template is crucial. Cedric Huyghebaert: “Since the start of the Flagship, we made substantial progress in growing high-quality graphene by means of chemical vapor deposition. This growth process still needs further engineering and fine-tuning, but I’m very confident that this is the way to go. The real challenge today is in developing a defect-free transfer technique that can replace the traditional lab-scale exfoliation process using cellophane tape. There are several possible strategies towards mass manufacturability, one of them relying on adhesion and interface chemistry. Since we joined the Flagship, we have greatly enlarged our insights in these processes and have identified the critical parameters that will take us towards a real breakthrough. Once we will have established a reliable transfer process, a next step will be to involve tool vendors and evolve from manual handling towards real automatic tools suitable for mass production.”

Market entry

Although researchers are still exploring the physics and applications of this material, it is generally expected that graphene-based applications will soon make it to the market. Cedric Huyghebaert: “A few products containing graphene have already entered some niche markets. Think about tennis rackets or bicycles where graphene is used to reinforce the material. Also, in China, you can already buy devices with touch screen displays where the transparent ITO (or indium tin oxide) electrode is replaced with a layer of graphene. In this application, graphene cannot yet compete with ITO in terms of performance or cost, but it is potentially more sustainable on a longer term.”

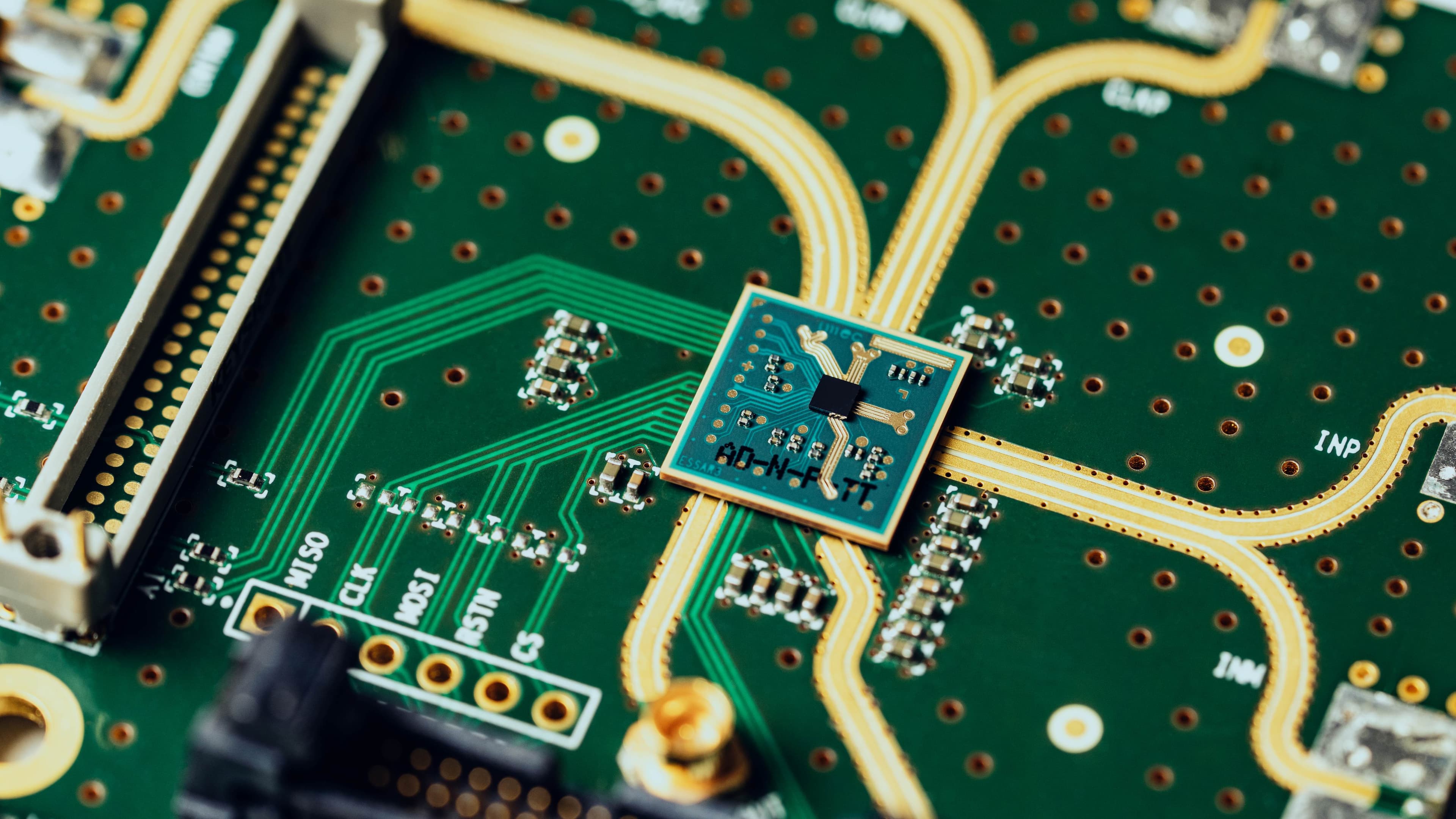

An interesting and larger market where graphene could make a difference, is opto-electronics and photonics. Due to the steep rise in data traffic, optical data transmission has become key. Graphene could play a role in the conversion of digital data into light modulation. Cedric Huyghebaert: “Graphene-based optical modulators with a performance at least comparable to traditional SiGe-based modulators have already been demonstrated, also at imec. For this type of applications, the wafer-scale integration of high-quality graphene and the ability to mass-produce graphene-based devices will be crucial. This could pave the way towards devices that will be far less expensive than today’s optical components. Once we will have established an integration process at wafer scale, other applications will make it to the market as well. Without a solution for the wafer-scale integration, the first graphene-based commercial products will most likely be introduced in other domains, such as photovoltaics and energy storage.”

Critical mass

Within the Flagship, the expertise of more than 150 partners – from universities, research institutes and industry – is bundled into 20 work packages. Cedric Huyghebaert: “This Flagship represents a new form of joint research on an unprecedented scale. Bringing together such a critical mass really helps to make progress in a field that is still precompetitive. We have learned a lot in the last few years, not only on graphene and how to integrate it in a production environment, but also on the way we should organize ourselves. For example, we have set up an informal working group on the topic of wafer-scale integration where we share our major concerns. This shows that joint initiatives are being taken on a European level which have not been there before. But it also provides a few challenges. Managing such a huge collaborative effort, for example. And, the partners within the Flagship have so far explored a broad range of opportunities not to miss out on any field which could bring breakthroughs relevant for Europe's industry. Now, the Flagship probably has to face the challenge of narrowing down the options to the most promising application areas.”

Published on:

12 December 2016