In the imec.icon project ARIA, the project partners used artificial intelligence for object recognition. ARIA, a project that ran from 2016 to 2018, focused on the application of augmented reality (AR) for industrial maintenance processes. Using a hololens or other AR-supported device, maintenance staff can be guided step by step through their work on machines and industrial installations. This allows them to carry out maintenance or repairs in a correct and safe manner, even if they are less familiar with the specific installation.

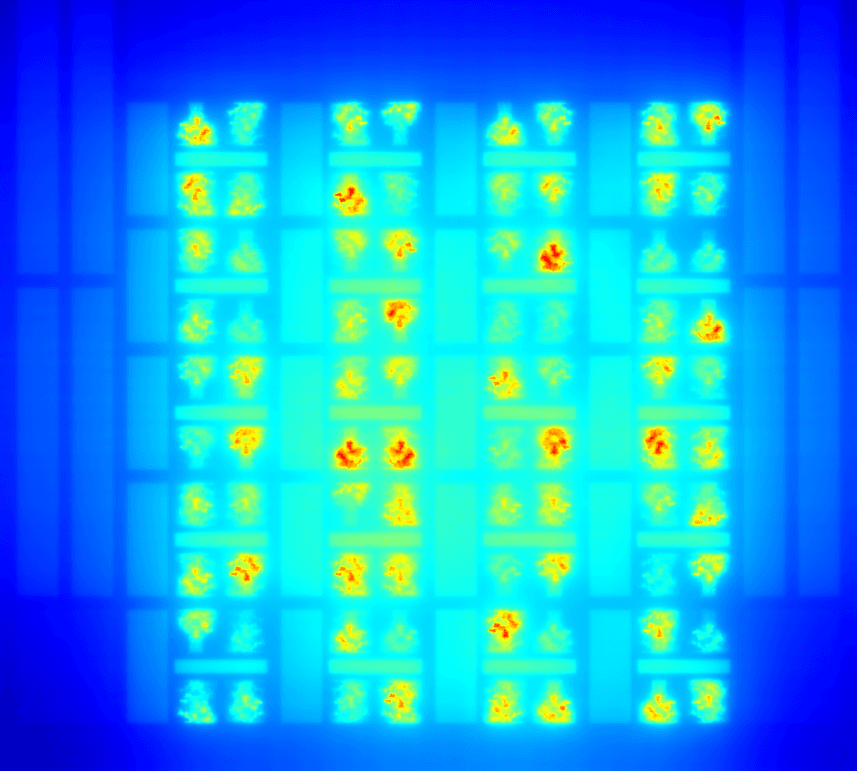

An important aspect in such a scenario is object recognition. More specifically, identifying the right parts and tools to perform a specific task. To complement the experience of the operational staff, the algorithm can identify objects from different view angles.

The AI algorithm was trained using a database of existing components, but can also identify and name new components that were not in the original database, even when there is only a family resemblance.

Using the wrong screw, or having one to spare at the end of a complex repair, should be a thing of the past.

The ARIA project was a collaboration between MICT and IPI, two imec research groups at Ghent University; ETRO, an imec research group at VUB and the industrial partners Evonik Degussa Antwerp, Impala and Neopica.

Want to know more?

- Project page of the imec.icon-project ARIA.

More about these topics:

Published on:

13 May 2019