Ultra-low background photonic integrated waveguides for on-chip Raman spectroscopy

Gent | More than two weeks ago

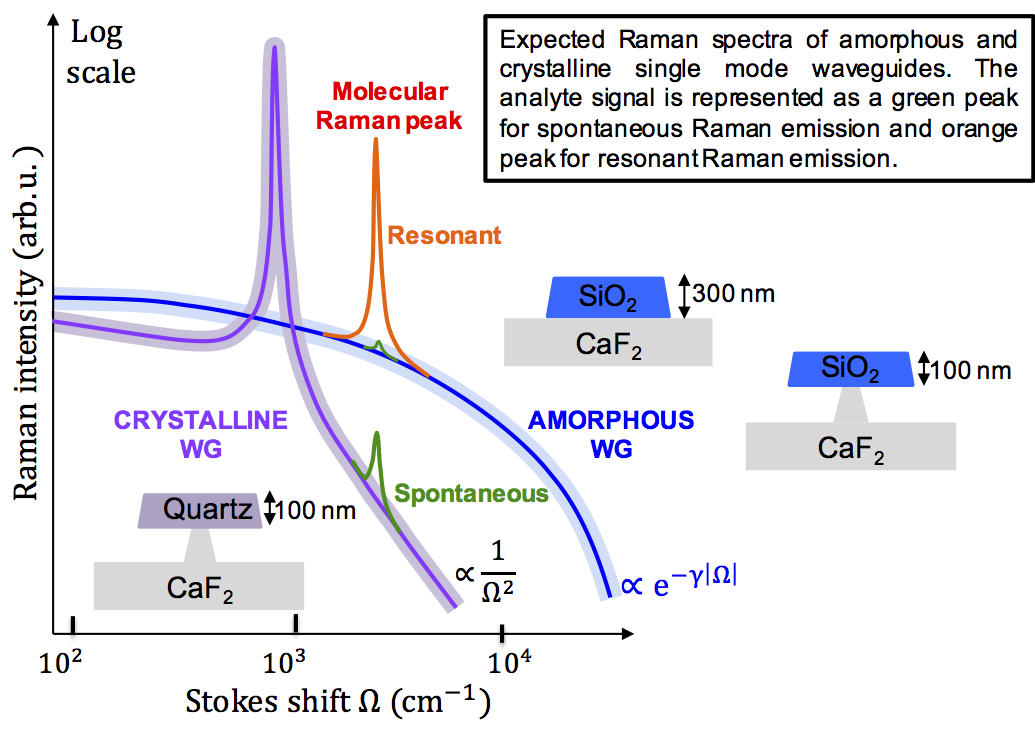

Raman spectroscopy is foreseen as a powerful non-invasive optical technique to probe with high specificities biological solutions resulting from body fluids or from biochemical industrial processes. This technique will enable a large number of sensing applications in the medical field, the pharmaceutical industry and the food industry. However, current Raman approaches suffer from insufficient detection limit or reproducibility. Integrated photonics can, in theory, overcome this problem by increasing the interaction length with the analytes, and the excitation and the collection efficiency of the Raman signal by using high index contrast waveguides [1]. For instance, Axithra, a recent spin-off from Ghent University and imec is making use of on-chip Raman sensing to monitor drug concentrations in blood. In practice, see the attached image, the presence of a background in the recorded optical spectra sets a fundamental detection limit that depends on the material used to form the core of the waveguide [2]. To increase the impact of Raman sensing, the state-of-the-art detection limit has to be improved by at least ten times. The state of the art is currently achieved with amorphous silicon nitride waveguides operating in the near infrared (NIR) wavelength range. Another potential material is silica, the thermal properties of which are suitable for reducing the impact of the background as recently discussed in [3]. Interestingly, silica is transparent down to the ultraviolet (UV) wavelength range in contrast to silicon nitride, which can be used to enhance the molecular Raman signal compared to the background via a resonant effect. Besides, an unexplored avenue are waveguides made crystalline material in place of amorphous material that are expected to have a completely different background as illustrated in the attached image.

In this project we will design and fabricate integrated photonic waveguides made of amorphous or crystalline material that are transparent in the UV and NIR and we will study their Raman spectrum both in the NIR and UV. We will start with waveguides made of silica and monocrystal quartz layers on calcium fluoride wafers and investigate their compatibility with mesoporous coating to enhance the concentration of the analyte in the sensing area of the waveguide [4]. We will also explore the possibility to fabricate calcium fluoride waveguides on thermal oxide wafers. Based on a fundamental investigation of the background in waveguides made of different materials and of different geometries, we expect to achieved world record detection limit values for on-chip Raman sensing.

[1] N. L. Thomas, Z. Liu, C. Lin, H. Zhao, and R. Baets, “Raman on-chip: current status and future tracks,” in Integrated Optics: Devices, Materials, and Technologies XXV, vol. 11689 S. M. García-Blanco and P. Cheben, eds., International Society for Optics and Photonics (SPIE, 2021), p. 1168908.

[2] N. Le Thomas, A. Dhakal, A. Raza, F. Peyskens, and R. Baets, “Impact of fundamental thermodynamic fluctuations on light propagating in photonic waveguides made of amorphous materials,” Optica 5(4), 328–336 (2018).

[3] M. Novik Jensen, J.C. Gates, A.I Flint, and Hellesø, “Demonstrating low Raman background in UV-written SiO2 waveguides”, OpticsExpress 31(18), 31092-31107 (2023).

[4] Z. Liu, H. Zhao, B. Baumgartner, B. Lendl, A. Stassen, A. Skirtach, N. Le Thomas, R. Baets, “Ultra-sensitive slot-waveguide-enhanced Raman spectroscopy for aqueous solutions of non-polar compounds using a functionalized silicon nitride photonic integrated circuit”, Optics Letters 46(5), p.1153 (2021).

Required background: Engineering Science, Applied Physics, Enginering Technology.

Type of work: 30% experimental, 30% design/modeling, 30% fabrication

Supervisor: Nicolas Le Thomas

Co-supervisor: Pol Van Dorpe

Daily advisor: Nicolas Le Thomas

The reference code for this position is 2025-138. Mention this reference code on your application form.