Bioprocess monitoring and control

Start from imec’s technology toolbox to develop solutions that will finally bring realtime inline/online monitoring and control to biomanufacturing.

Continuous quality and process control is a surefire way to intensify and enhance the efficiency of an industrial process. It allows constant – even automatic – adjustment of the production steps. And therefore increases yield, reduces waste, and cuts cycle times.

However, such near-real-time process monitoring is difficult to achieve in biomanufacturing. Both the upstream and downstream production steps are incredibly complex. Their sensitivity to the slightest variations necessitates the use of highly sophisticated monitoring equipment. Such tools are expensive and need specialized operators.

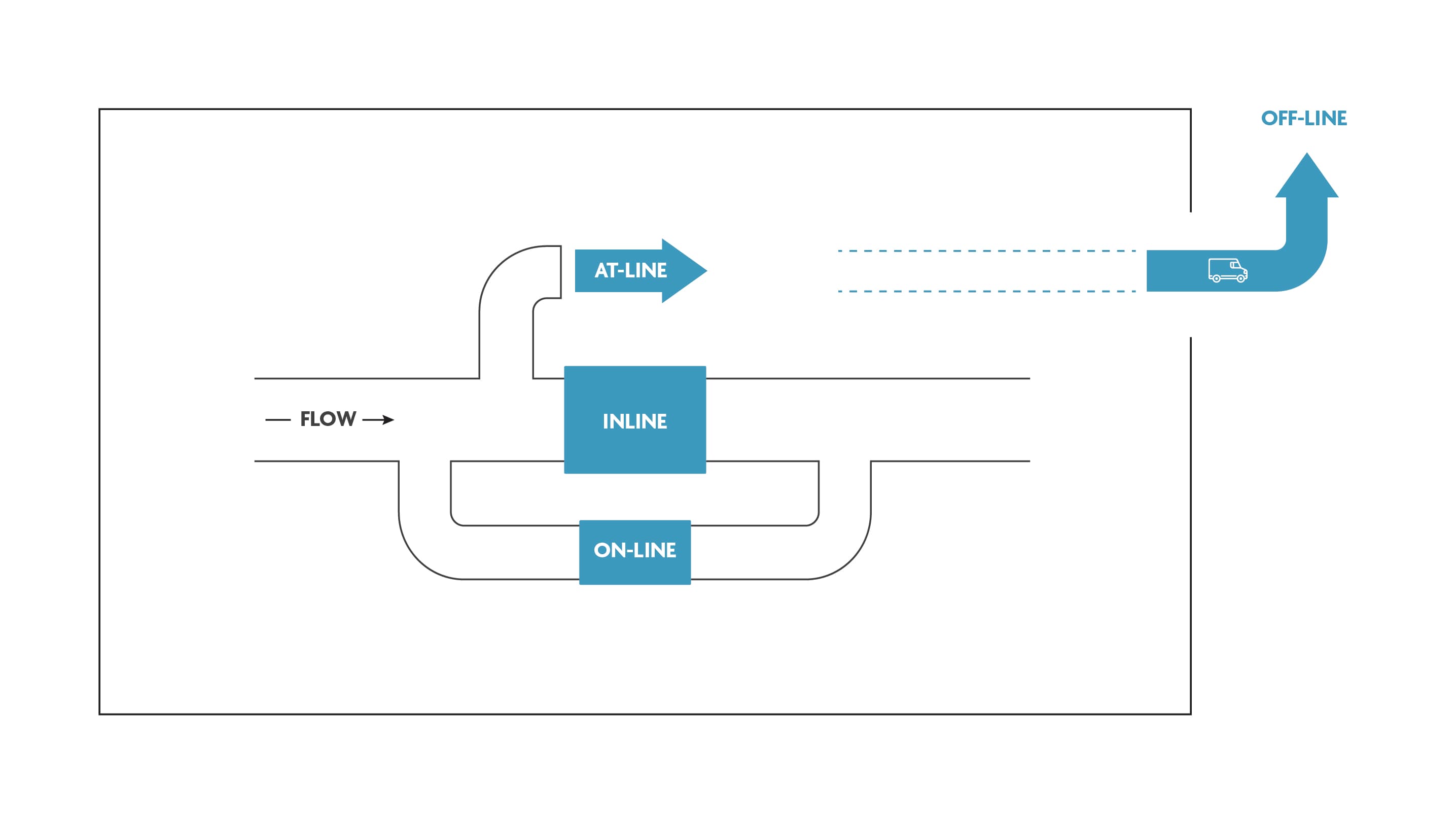

Therefore, offline bioprocess monitoring and control is still the norm. Samples are taken out of the flow and analyzed manually – often even in specialized offsite labs. This disturbs the process flow. For personalized treatments such as cell and gene therapy, it can mean that valuable time is lost for the patient.

Last but not least, it results in a lot of extra costs, both total product costs and investment costs for new facilities.

That’s why online or inline bioprocess monitoring has long been the holy grail of the biomanufacturing industry. Thanks to chip technology, such bioprocess monitoring technologies are finally within its reach.

Bert Verbruggen, imec's program manager for biomanufacturing solutions, talked about the challenges of biomanufacturing and how inline production process monitoring can help solve these issues, with Electronic Engineering Journal. Listen to the podcast.

Semiconductor technology revolutionizes biomanufacturing

With our smartphone, we now have a single device in our pocket that allows us to communicate, access all the world’s information, take pictures, ... Such is the power of semiconductor technology. It can bundle many functionalities in one device or even a single chip – extremely affordable because of mass production.

Moreover, chips can contain much more than electronic circuits. Thanks to the integration of microfluidics, photonics, sensors and actuators, ... they can be made into microdevices that autonomously interact with their environment. In the context of biomanufacturing: lab-on-chips that behave as miniature, but highly accurate versions of PCR reactors, separation modules, cell sorters, spectroscopes, microscopes, ... Ideal to integrate into the bioprocessing flow.

Imec’s toolbox for bioprocess monitoring

Imec’s research has resulted in several technologies that are ready to be tuned and developed for use in biomanufacturing.

Advanced process analytical tools

A quickly adaptable process makes for a predictable outcome. That’s why there’s a need for process analytical technologies (PAT) that keep a constant eye on multiple key parameters. By leveraging the compactness and affordability of chip technology, imec is developing a multiparameter solution for inline sensing. It enables the constant monitoring of an expanding number of parameters such as:

- pH

- dissolved oxygen

- glucose

- lactate

- cell density

- proteins

Imec’s multi-PAT solution is conceived as a single probe that’s immediately deployable, remains stable for at least four weeks and can wirelessly transfer data.

- Left: close-up of the 2nd-generation PAT sensor

- Right: the sensor chip on a PCB

At-line bioburden monitoring

Because bacterial monitoring of a manufactured batch is currently performed off-line, it takes seven to twenty weeks before it can be released. Imec proposes a combination of two technologies to speed up this process:

- Lens-free imaging with a large field of view to detect suspicious particles.

- On-chip PCR to speciate these particles.

Both processes are performed at-line, automatically and in less than 20 minutes. The result can be automatically entered in a laboratory information management system (LIMS). And the PCR-amplified sample can be collected for further analysis.

Imec’s integrated microsystem for detection of multiple single nucleotide polymorphisms directly in human blood.

At-line contamination monitoring

Imec’s toolbox contains three solutions for continuous monitoring of contamination in a bioprocess:

- On-chip photonic immuno-assays for protein sensing. With a sample-to-result in less than 10 minutes.

- Digital PCR for residual DNA monitoring.

- Lens-free imaging for the detection of subvisible particles.

At-line/in-line aseptic monitoring

Bacterial environment monitoring is currently performed using settle plates and visual inspection of colony-forming units (CFUs) – which is time-consuming and relies on highly qualified personnel.

Imec’s goal is to enable real-time, automatic detection of microbiological growth using lens-free imaging. Dramatically speeding up the process and eliminating the cumbersome handling of petri dishes.

Imec’s toolbox for bioprocess control

Cell and gene therapy

Personalized cell and gene therapies are widely considered our best weapon against diseases such as cancer. However, their cost is incredibly high, and their manufacturing process can easily take ten days – from needle to needle.

Imec’s modules to increase the availability and speed of cell and gene therapies, and move to a decentralized approach, include:

- technologies for fast and accurate selection of cells, such as our cell sorter

- technologies for optimum transfection of single cells, such as our multi-electrode array (MEA)

- technologies for continuous process monitoring, with wireless, privacy-preserving read-outs.

Download our white paper on technologies for cell and gene therapy

Data analytics

Bioprocesses often exhibit a staggering complexity. That makes it impossible for even experts to predict their outcomes. But by combining biological expertise with data-driven modeling, the level of uncertainty can be significantly reduced.

Imec’s researchers apply artificial intelligence to predict biomanufacturing processes based on historical and real-time sensor data. This close monitoring enables more timely interventions that prevent, for instance, the destruction of complete batches due to contamination.

One step further is complete lab automation supported by a closed-loop system between sensors and actuators. Meanwhile, imec’s compute system architecture team investigates the groundbreaking computational models we will eventually need to realize the astronomical AI workloads involved in the real-time control of bioprocesses.

Work with us

Imec’s mission is to support the improvement of healthcare by making biomanufacturing processes faster and more cost-efficient. To accomplish that, we:

- Address generic industry needs through pre-competitive joint research.

- Solve dedicated partner challenges through bilateral R&D projects.

Want to join our research or leverage our R&D services?